Why Use!! Rubber Chemical Dispersion in Latex Industry

June 08, 2022 · Preethy Paul

Chemicals used by the latex industry are generally not soluble in water, hence they are converted into high quality dispersion so that the crosslinking reaction is more efficient.

ASSOCIATED RUBBER CHEMICALS KOCHI PRIVATE LIMITED produces a range of dispersion from preservative system to compounding composites.

A broad classification of the range of dispersion manufactured by Associated is:

- Preservative system for Field Latex

- TMTD based

- TMTD free

- Ammonia free

- Preservative system for Centrifuged Latex

- TMTD based

- TMTD Free

- Ultra Low Ammonia

- Ammonia free

- De proteinising dispersion

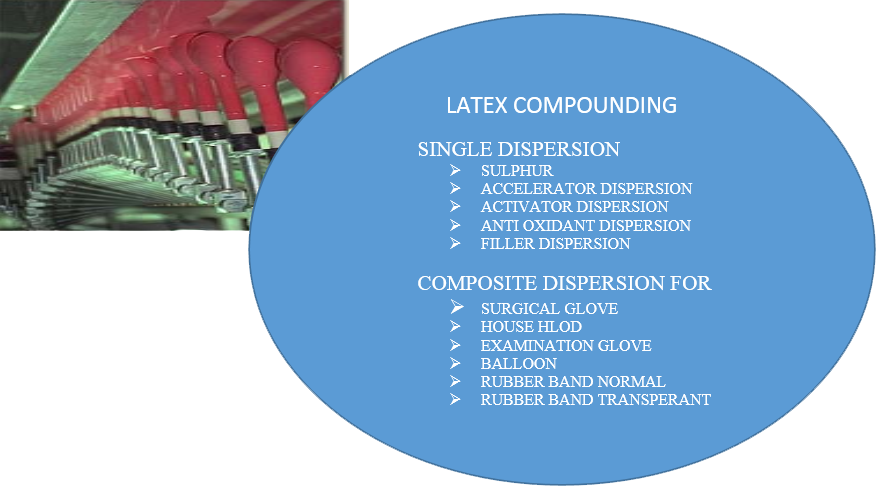

- Compounding dispersion

- Individual dispersion – Sulphur, Zinc Oxide, Accelerators, Fillers etc

- For gloves, balloons, condoms, foam etc etc.

- Low Nitrosamine dispersion for all latex goods

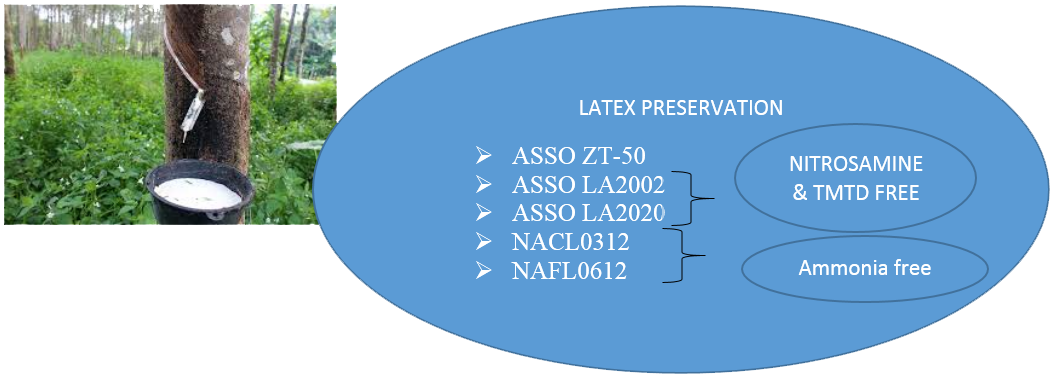

Latex Preservation

Natural rubber latex contains non rubber constituents like proteins, carbohydrates etc, and microorganism which contaminate latex feeds on them to release Volatile Fatty Acids which in turn coagulates of latex. In order to prevent the coagulation latex it is preserved with a suitable preservative. Check out rubber chemical dispersion manufacturer in Kerala.

Commonly used preservative system as follows:

- High ammonia preservative system (HA)

- Low ammonia preservative system

High preservation has gradually been replaced by Low Ammonia System due to the drawback of Ammonia pollution in the factory and the Zinc Oxide thickening during compounding.

The commonly used Low Ammonia preservation System is a combination of Ammonia, Zinc Oxide and TMTD commonly known as LATZ. Most of the Indian processors use this system

Associated offers it as ASSO ZT 50

The use of TMTD has been restricted in most of the European and American countries. Associated has developed two TMTD free system and is exporting them to many countries. They are code named.

- Asso LA 2002

- Asso LA 2020

Ammonia has now been included in the restricted list and many customers prefer either Ultra Low Ammonia (ULA) or Ammonia Free latex (AF).

With this requirement Associated has developed Ammonia Free preservation systems

- Asso NAFL0612

- Asso NACL0312

The former for field latex preservation and the latter for Centrifuged Latex preservation.

Associated offers both high quality single and composite dispersion for latex products manufacturing.

Dispersions are manufactured using most modern technology in highly sophisticated mills. The particle size is in the ideal range to prevent any agglomeration or caking.

PROTEIN ALLERGY

Protein Allergy is a serious issue in the west and due to this scare synthetic latex is replacing Natural Rubber Latex especially in the glove market.

Associated manufactures deproteinizing dispersion for VYSTAR USA and supply worldwide to licensed manufacturers. The deproteinizing dispersion is a patented product of VYSTAR CORPORATION and the process of deproteinizing is an online process unlike the enzyme process. It has a number of advantages over the enzyme process

The dispersion is code named Asso VYULP 0303 100

ASSOCIATED DISPERSION

- Associated is in possession of the latest technology for production of dispersion

- Associated has the most modern imported machinery for the production of dispersion

- Associated engages highly qualified and experienced Technologists

- The Quality Assurance System is world class with monitoring at every stage of production

- Associated is a ISO 9000 2015 Company

QUALITY OF DISPERSION

- A good quality dispersion should have particle size around 3 to 5 microns

- Due to density difference the dispersion is likely to settle with time but it should be easily redispersable.

- The dispersion should be compatible with latex. There should not be any shock to the latex.

- There should not be any agglomeration of the particles

WHY SHOULD YOU OUTSOURCE THE DISPERSION

- Number of processes can be reduced. Especially for the start up industries.

- Investment can be reduced – Machine, Man, Power.

- The tedious task of sourcing each chemical, quality check, storage, dispersi9n making etc can be avoided.

- Space utilization can be improved

- Reduce effluent

- Avoid waste

- The financial aspect of storing all the required chemicals can be avoided.

- As our dispersion’s particle size is OPTIMUM, the dosage can be reduced.

- The primary focus of every manufacturer should be to concentrate on their product be it gloves, condoms, balloons etc and leave the dispersion to its experts.

DISPERSION FOR VARIOUS AREAS THAT ASSOCIATED SUPPLY

SINGLE DISPERSION

| CODE | CHEMICAL/PERCENTAGE | USE | PACKING |

|---|---|---|---|

| ASSO VUL 50 | SULPHUR 50% | VULCANISING AGENT | 50 kg |

| ASSO ACTI 50 | ZINC OXIDE 50% | ACCELERATOR | 50 kg |

| ASSO DE 50 | ZDEC 50% | ACCELERATOR | 50 kg |

| ASSO ACCEL DB 50 | ZDBC 50% | ACCELERATOR | 50 kg |

| ASSO ACCEL ZMB 50 | ZMBT 50% | ACCELERATOR | 50 kg |

| ASSO ACCEL TMTD 50 | TMTD 50% | ACCELERATOR | 50 kg |

| ASSO AO I 50 | IONOL LC 50% | ANTIOXIDANT | 50 kg |

| ASSO TD R 50 | TITTANIUM DIOXIDE 50% | PIGMENT | 50 kg |

| ASSO MCC 75 | CALCIUM CARBONATE 75% | FILLER | 50 kg |

| ASSO PCC 50 | PRECIPITATED CALIUM CARBONATE 50% | FILLER | 50 kg |

| ASSO CCL 50 | CLAY 50% | FILLER | 50 kg |

COMPOSITE DISPERSION

| CODE | CHEMICAL/PERCENTAGE | USE | PACKING |

|---|---|---|---|

| ASSOCURE SGJJ 50 | COMPOSITE DISPERSION 50% | GLOVE | 50 kg |

| ASSOCURE SGRB3 50 50 | COMPOSITE DISPERSION 50% | GLOVE | 50 kg |

| ASSOCURE SGPJ 50 | COMPOSITE DISPERSION 50% | GLOVE | 50 kg |

| ASSOCURE BN 50 | COMPOSITE DISPERSION 50% | BALLOON | 50 kg |

| ASSOCURE BAND | COMPOSITE DISPERSION 50% | RUBBER BAND NORMAL | 50 kg |

| ASSOCURE BAND TT | COMPOSITE DISPERSION 50% | RUBBER BAND TRANSPERANT | 50 kg |

| ASSOURE CB 50 | COMPOSITE DISPERSION 50% | CRPET BACKING | 50 kg |

Quick Enquiry

To know more about Associated Chemicals feel free to send a message

Our Sister Concerns

Our Sister Concerns

Usefull Links

Get In Touch

Assochem Chambers, Bypass, Edapally,

Kochi-682024, Kerala, India.

Phones : +91 9495999349, +91 9388610189, +91 484 2339190, +91 484 2348028

E-mail : nsn@assochem.in, marketing@assochem.in, mail@assochem.in

Support